TENLUXE® Textile Cleaning Gun® Type A

Product Introduction

Feature

Spec.

Cup Capacity: 1,000cc

The cleaning gun reciprocates 60 times a second so its performance depends on design, construction and regular maintenance. Each Tenluxe cleaning gun is made from hundreds of precisely engineered parts. Strict quality controls during assembly ensure the highest quality.

■ the Use of the Cleaning Solvents

Step 1 Hold down the trigger switch and the solvent will start spraying after 5 seconds.

Keep a distance of 10 ~ 20 cm from the target. Adjust solvent strength by changing the distance.

Step 2 The volume can also be adjusted. Rotate volume control knob anti-clockwise to increase volume. Rotate clockwise to reduce volume and spray strength.

Step 3 Clean from the edges first. For lighter solvents, reduced the volume slightly. If volume is too high actual spray strength is reduced.

Step 4 If the nozzle head is blocked, remove the nozzle head and clear obstruction with a toothpick or another cleaning gun. Do not use a hard metal needle.

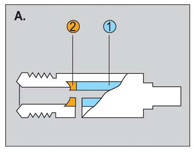

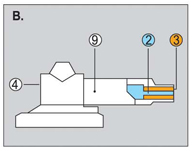

■ Type A Pump Cylinder

>

>

- Copper alloy pump cylinder can stand wear and tear (See Drawing A① ) with wear-resistant chromium ring A② equipped. It delivers an excellent seal and good suction.

- Unique adjustment eye (See B⑨) for easy adjustment.

- Durable and precisely engineered transmission body with copper alloy components for wear-resistance. (See B③) The transmission's guiding track (See B②) and the inner hole (See B ④) where the cylinder is installed have been precisely polished.

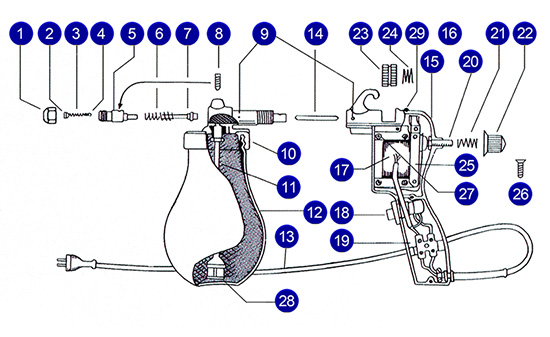

■ Type A Part List

② Swirl head

③ Delivery valve spring

④ Delivery valve cone

⑤ Pump cylinder

⑥ Piston spring

⑦ Piston

⑧ Pump unit locking screw

⑨ Adjusting eye

⑩ Front body

⑪ Suction Pipe

⑬ Electric lead

⑭ Intermediate push rod

⑮ Gun housing

⑯ Gun housing cover

⑰ Electric drive unit

⑱ Tigger switch

⑲ Terminal block

⑳ Armature buffer stob

㉑ Volume control spring

㉒ Volume control knob knob

㉔ Adjusting roller spring

㉕ Vibrating plate

㉖ Cover fixing screws

(countersunk, 3)

㉗ Lock washer

㉘ Filter

㉙ Lubrication hole

At the end of each working day or after a single use, spray a mixture of solvent and 5~10% machine oil to prevent rusting of the pump cylinder. 5 drops of lubricating oil should also be applied to the lubricating hole after every 5 gallons of solvent sprayed.